Introduction: The Intersection of Fashion and Therapy

The demand for "functional wellness" apparel is surging. Driven by the popularity of weighted blankets, consumers are now seeking wearable Deep Pressure Therapy (DPT) products. However, for fashion brands and procurement managers, sourcing high-quality weighted hoodies presents a unique manufacturing challenge.

Unlike standard apparel, a weighted hoodie is a hybrid product—part garment, part medical device.

The central dilemma in manufacturing is the trade-off between density and design. How do you increase weight without making the user look like they are wearing an inflated suit? Based on our production experience, there are only two viable manufacturing paths, each with specific use cases and technical requirements.

Method A: The High GSM Approach (Pure Fabric Weight)

The simplest way to add weight is to increase the density of the fabric itself. In the textile industry, this is measured in GSM (Grams per Square Meter). Standard hoodies range from 280–350 GSM.

The Material Spec

To create a "weighted" feel using only fabric, manufacturers use ultra-heavyweight cotton fleece or French Terry, ranging from 500 GSM to 900 GSM.

The "Ceiling" Issue

While high GSM fabrics offer a premium, structured "streetwear" look, there is a physical limit.

-

The Limit: Once a hoodie exceeds roughly 1.5kg (3.3 lbs) in total weight via fabric alone, the material becomes excessively thick and stiff.

-

The Result: The garment loses its drape. It becomes difficult to fold, expensive to ship due to volume, and can feel restrictive rather than comforting.

Verdict: This method is ideal for luxury streetwear brands looking for a premium "heavy hand" feel, but it is insufficient for true therapeutic anxiety relief which often requires 3kg–5kg loads.

Method B: The Bead-Filling Approach (The "Gravity" Design)

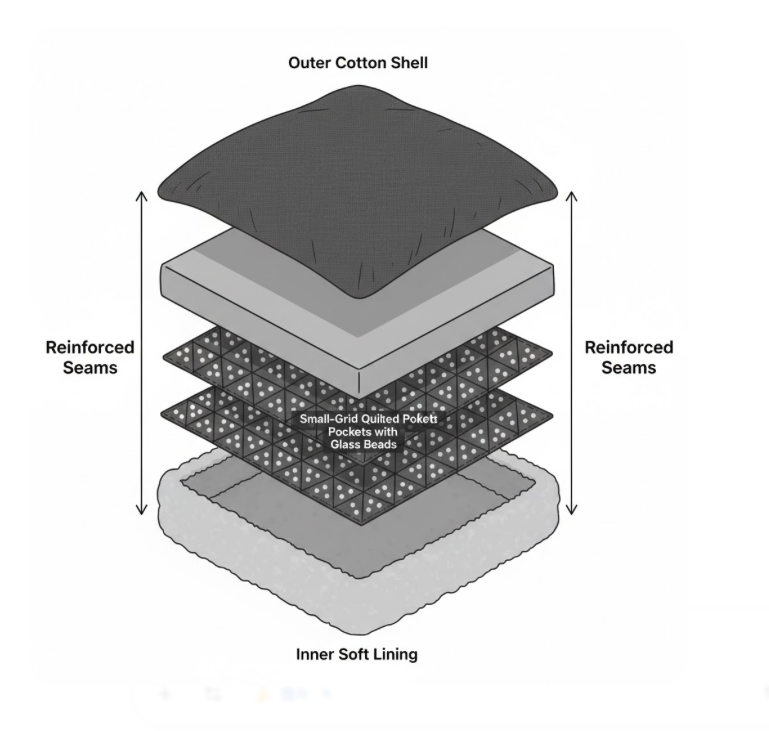

To bypass the fabric weight limit, we must adopt construction techniques similar to weighted vests or blankets. This involves inserting high-density weighting materials into the lining of the hoodie.

The Filling Materials

Choosing the right filler is critical for user experience and washability.

-

Glass Beads (Recommended): The industry standard for high-end anxiety apparel. They are hypoallergenic, silent, and wash-durable. They provide excellent density without bulk.

-

Iron/Steel Micro-Pellets: Used for extreme weight requirements. They offer the highest density (making the garment thinner for the same weight), but require specialized coating to prevent rust during washing.

-

Plastic Pellets (Poly): A budget option. We generally advise against this for fashion items because plastic has low density, requiring a higher volume of beads to achieve the target weight, resulting in a bulky, "puffy" look.

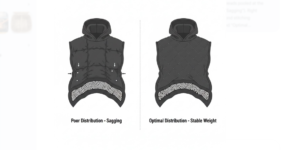

Critical Engineering: Why "Small-Grid" Quilting is Mandatory

This is the most common failure point we see in prototypes from inexperienced factories.

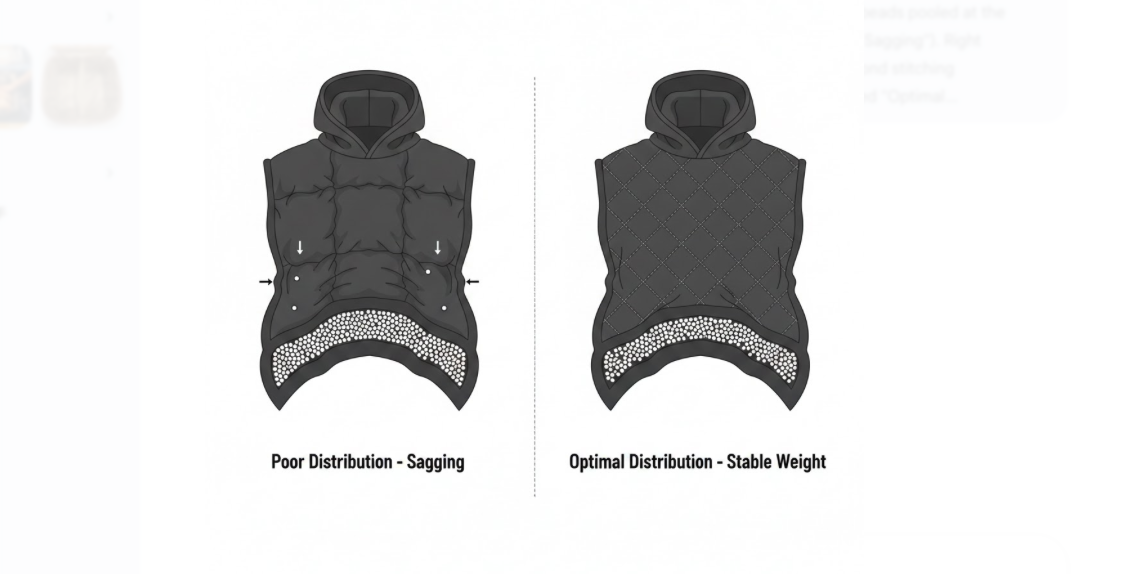

If you simply fill a hoodie lining with glass beads, gravity takes over. The beads slide to the lowest point, causing the hem to sag and the shoulders to feel light. This creates an unbalanced load that strains the wearer’s neck.

The Solution: Constrained Quilting

To maintain even weight distribution—similar to a tactical gravity vest—the internal structure must be quilted. However, the size of the quilt grid is non-negotiable.

Expert Insight: The quilting grid dimensions must be significantly smaller than those used in standard puffer jackets.

-

Large Grids (Fail): Allow beads to pool in the bottom corners of the square. The weight shifts dynamically as the user walks, creating momentum that pulls the garment off center.

-

Small Grids (Success): By reducing the grid size (e.g., 2-inch or 3-inch squares), we lock the beads into a tighter area. This prevents "pooling" and ensures the weight remains distributed across the trapezius and torso, providing the intended calming hug effect.

Diagram comparing large vs small quilting grids for weighted hoodie manufacturing showing bead distribution.

Diagram comparing large vs small quilting grids for weighted hoodie manufacturing showing bead distribution.

Comparison: Fabric Weight vs. Bead Filled

Use this table to decide which manufacturing route aligns with your product goals.

| Feature | Method A: High GSM Fabric | Method B: Bead-Filled System |

|---|---|---|

| Max Weight Potential | \~1.5kg (3.3 lbs) | 5kg+ (11 lbs+) |

| Primary Benefit | Style, durability, classic look | Therapeutic anxiety relief (DPT) |

| Thickness/Bulk | Very Thick / Stiff | Moderate (depending on bead density) |

| Manufacturing Cost | High (Fabric cost is dominant) | Medium-High (Labor cost is dominant) |

| Washability | Simple (Standard Wash) | Complex (Requires reinforced stitching) |

| Design Risk | Stiffness / "Cardboard" effect | Leaking beads / Sagging |

| Ideal Audience | Streetwear / Fashion Consumers | Wellness / Neurodivergent / ADHD |

Buyer’s Quality Control Checklist

When reviewing samples from your manufacturer, use this checklist to ensure durability.

-

Shake Test: Vigorously shake the sample. Do you hear beads moving? Ideally, the movement should be minimal (silent).

-

Stitch Density: Bead-filled segments require high SPI (Stitches Per Inch) or double-locking stitches to prevent beads from leaking out.

-

Lining Strength: The internal fabric holding the beads must be reinforced. Standard lining nylon will tear under the friction of glass beads over time.

-

Grid Consistency: Measure the quilting grids. Are they uniform? Uneven grids lead to uneven weight loads.

-

Wash Durability: Request a wash test report. Are the beads rust-proof? Does the fabric shrink, distorting the bead pockets?

FAQ: Sourcing Weighted Hoodies

Q1: Can I make a 5kg hoodie using just cotton fabric?

Answer: No. To reach 5kg with cotton, the fabric would need to be several inches thick. It would be impossible to sew and impossible to wear. For weights above 1.5kg, you must use a bead-filling technique.

Q2: Do glass beads make noise when walking?

Answer: Not if manufactured correctly. High-quality glass beads are very fine (sand-like texture). When packed tightly into small quilted grids with a soft batting layer, they are silent. Larger plastic pellets tend to make a "bean bag" sound.

Q3: What is the MOQ (Minimum Order Quantity) for custom weighted hoodies?

Answer: MOQs are typically higher for bead-filled hoodies (often 300–500 pcs) compared to standard cut-and-sew, because the quilting pattern requires custom tooling or automated template sewing setups.

Q4: How do we handle sizing?

Answer: Weighted hoodies should fit closer to the body than oversized streetwear to maximize the proprioceptive (hugging) effect. We recommend creating a specific size chart that accounts for the inner volume of the weighted layers.

Q5: Are these products safe for children?

Answer: Safety is paramount. For children's weighted apparel, the weight must not exceed 10% of body weight. Manufacturers must strictly adhere to safety standards regarding bead leakage (choking hazard) and flammability.

RFQ Template (Copy & Paste)

Use this template to get accurate quotes from manufacturers.

Subject: RFQ for Custom Weighted Hoodie Production - [Your Company Name]

Product Specs:

Target Weight: [e.g., 2kg / 4kg]

Construction Method: [Bead-Filled / Heavy GSM Fabric]

Filling Material (if applicable): [Glass Beads / Iron Pellets]

Outer Fabric: [e.g., 100% Cotton, 400 GSM]

Quilting Design: [Small Diamond Grid / Box Grid] - Critical for stability

Quantity: [e.g., 500 pieces]

Target Market: [Adults / Children]

Questions:

Please confirm your experience with small-grid quilting for heavy apparel.

Do you have in-house testing for bead leakage?

What is the lead time for a prototype?